What the heck is an 'over-center mechanism'?

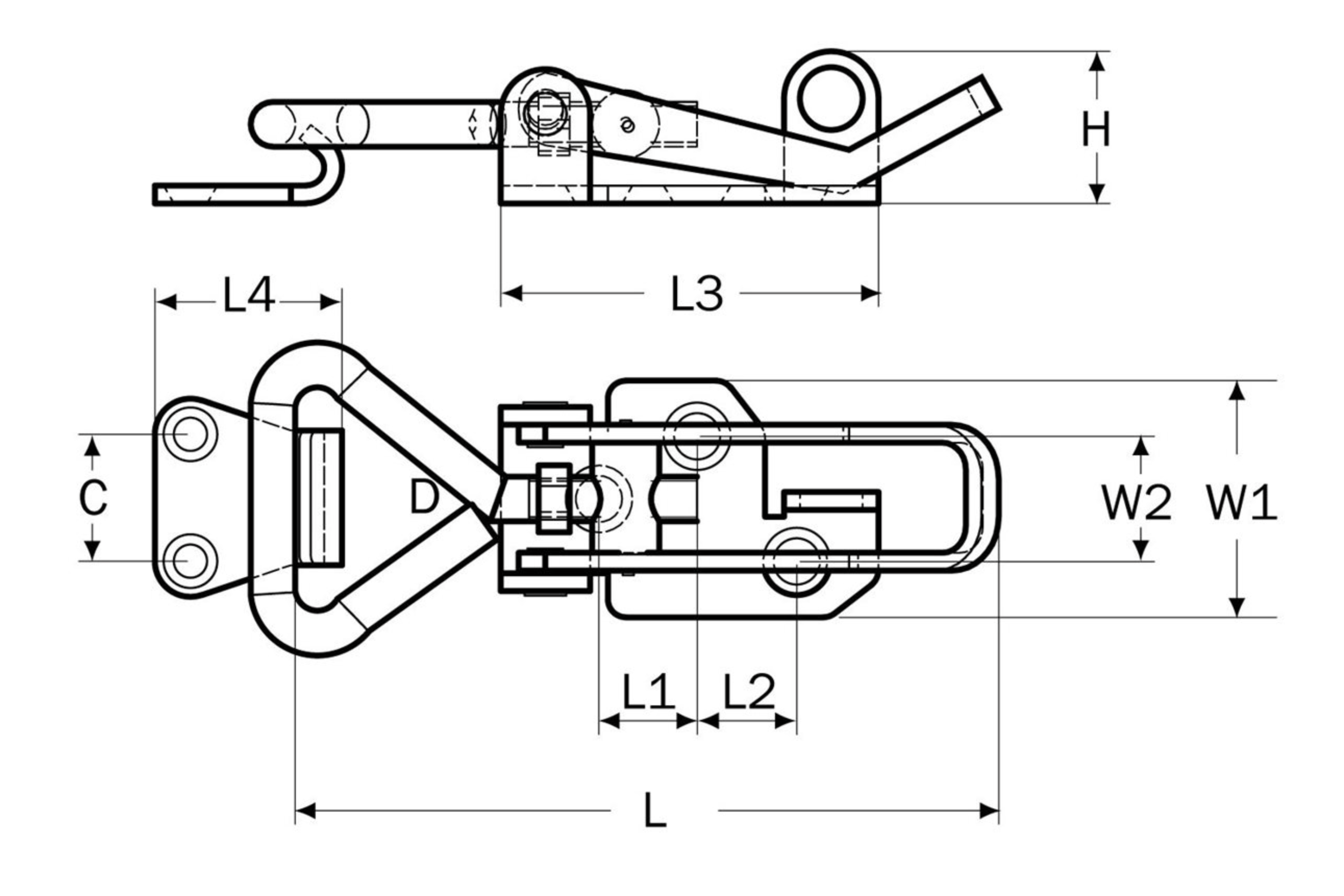

An over-center mechanism is a type of mechanical linkage that provides a locking or latching function by utilizing a specific geometric configuration. Most of us instantly know when we see something like the image above. The key components of an over-center mechanism include:

Three pivot points

Two fixed-length links

One variable-length link

The mechanism operates on the principle of mechanical advantage, where the force required to actuate the linkage changes as it moves through its range of motion. Here's how it works:

As the mechanism approaches the "over-center" position, the force required to move it increases.

At the over-center point, all three pivot points align in a straight line.

Once the mechanism passes the over-center point, the force required decreases, creating a self-locking effect. Or ‘hyperextension’ as one might say

This behavior results in two stable positions (bi-stable) on either side of the over-center point, allowing the mechanism to snap into place and remain locked until sufficient force is applied to move it back over the center. In this state the mechanism has stored elastic potential energy. Over-center mechanisms are commonly used in various applications, including:

Latches on tool cases and toolboxes

Vise grips or locking pliers

Folding chairs and tables

Safety gates and barriers

Clamping mechanisms in welding fixtures and jigs

Gas struts for assisted opening and closing of hatches or doors

Toggle switches

Locking mechanisms in furniture

The design of an over-center mechanism requires careful consideration of factors such as required force, travel distance, and the size and shape of the links and pivoting joints. By understanding and manipulating the over-center principle, engineers can create robust locking mechanisms or devices that release significant potential energy with minimal input force.